Waysia Industrial Co., Ltd. (WSI), founded in 1991, is a wholly owned subsidiary of the Meita Group—a global manufacturer with more than 5,000 employees, annual sales exceeding $700 million, and production capacity surpassing 8,000 tons per month.

As the innovation and R&D center for Meita, WSI brings over 30 years of CNC machine design, automation, and process engineering expertise. Originally focused on building precision tooling and special-purpose machines for Meita’s global operations, WSI has evolved into a builder of advanced 5-axis machining centers and vertical turning lathes used by manufacturers around the world.Every WSI machine is built on heavy, high-rigidity castings and assembled under strict ISO-certified quality systems. The result is higher accuracy at lower cost, delivering performance and longevity that production shops can depend on.

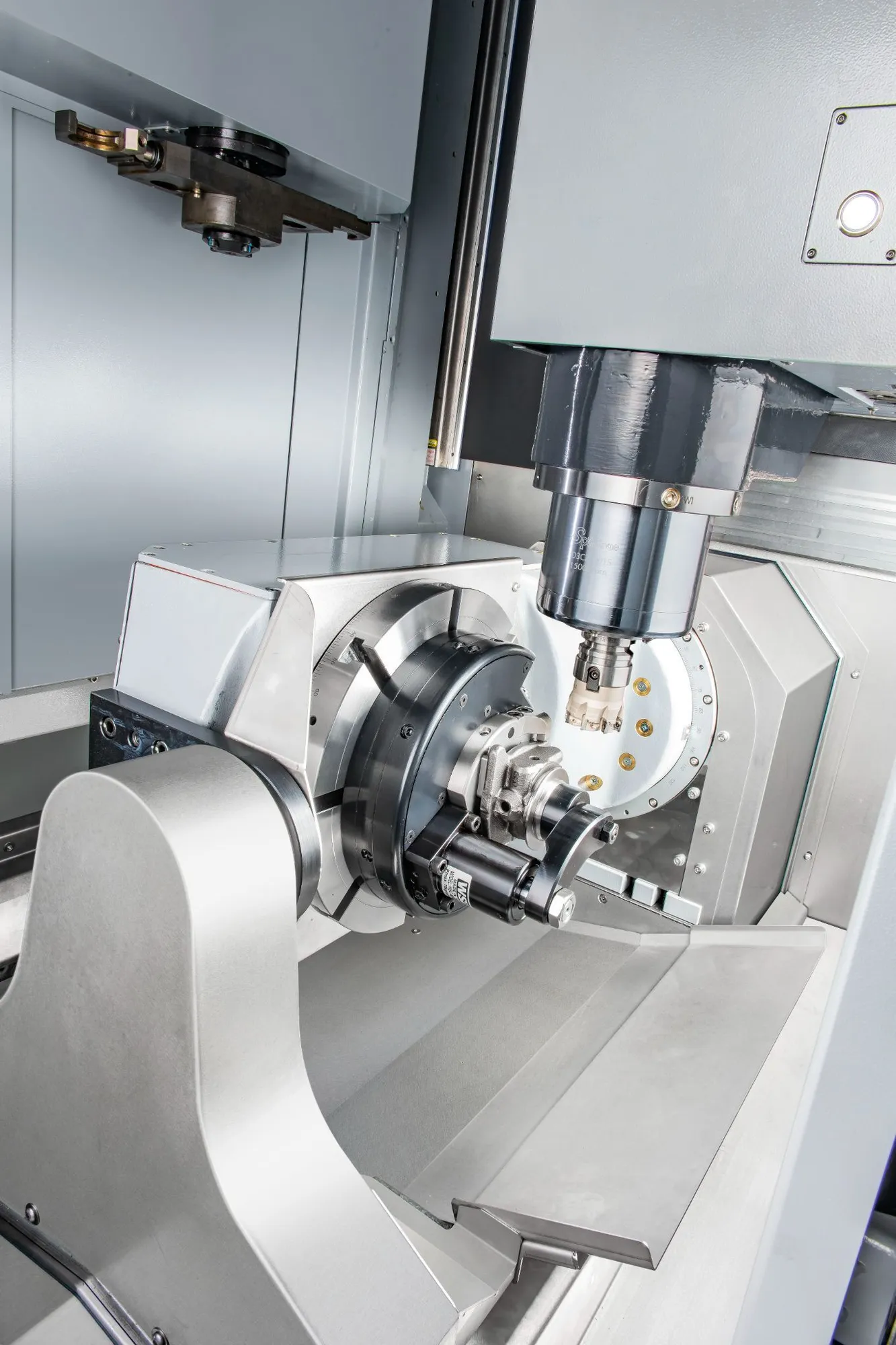

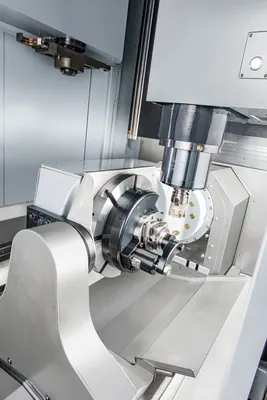

Compact 5-Axis Capability with Big-Machine Performance

.png?locale=en)

The WVM Series combines precision, rigidity, and flexibility in a compact 5-axis machining platform. Designed for high-speed contouring, tight-tolerance work, and continuous operation, each model offers a different balance of spindle taper, tool capacity, and table size to fit your production needs.

Key Features

Models

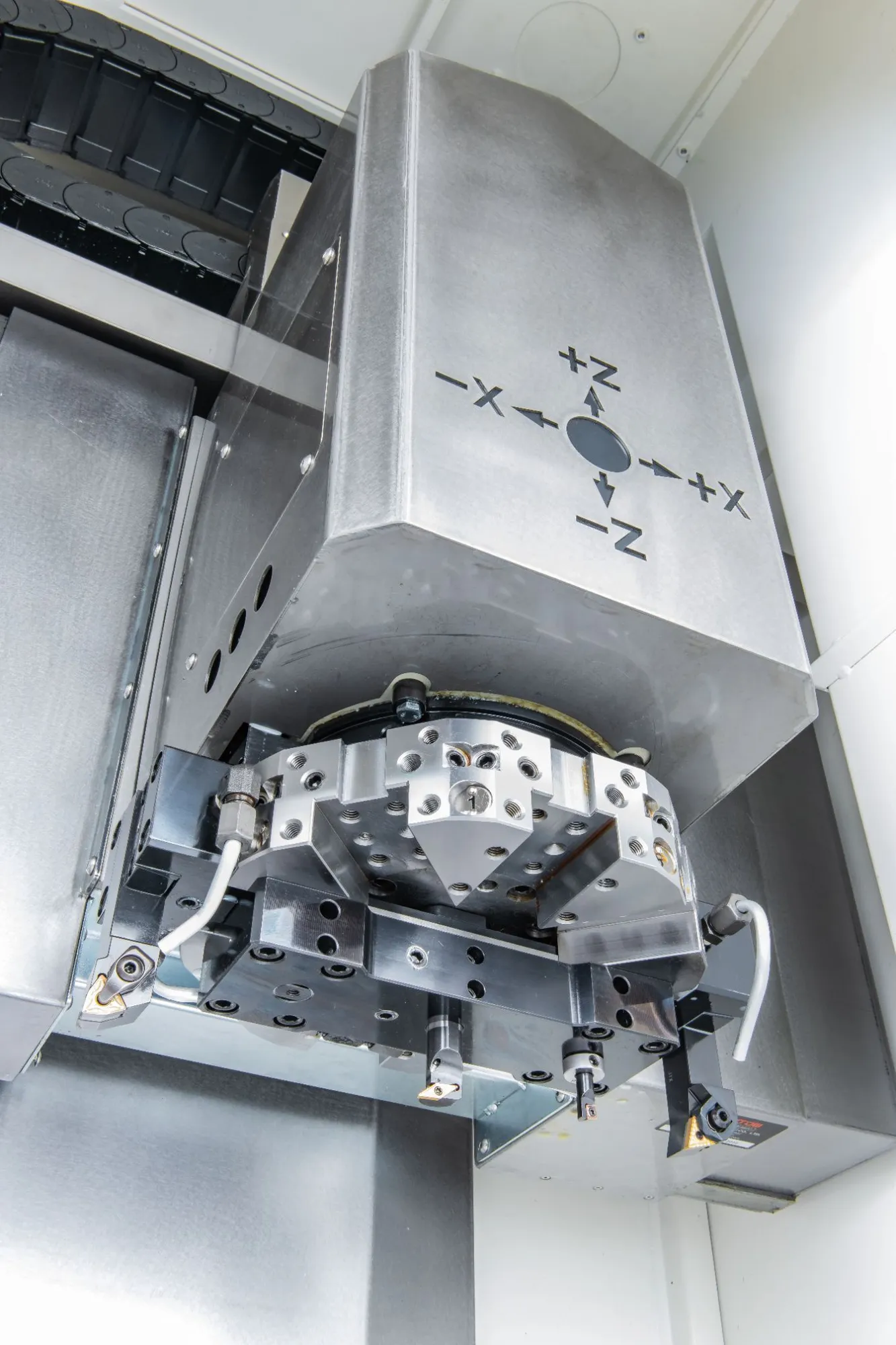

Compact, Rigid, and Built for Production Turning

The WVT Series delivers the power of a vertical turning lathe in a space-saving design, ideal for precision components and small to medium workpieces. With spindle options up to 4,500 rpm and heavy-duty cast iron construction, these machines handle high cutting loads while maintaining micron-level precision.

Key Features

Models

We use cookies to improve your experience. Privacy Policy.